Technical Services

Hezi technology focuses on the research and development of "rapid seamless conveyor belt joint sleeve" innovative technology project

TECHNICAL SERVICE

Technical Services

Detailed introduction

How to connect the connector of the conveyor belt?

Release time:

2019-08-07

All conveyor belts must be connected in a loop to be actually used, so the joint of the conveyor belt is a very critical preparation link. The quality of the joint directly affects the service life of the conveyor belt and whether the conveyor line can run smoothly.

All conveyor belts must be connected in a loop to be actually used, so the joint of the conveyor belt is a very critical preparation link. The quality of the joint directly affects the service life of the conveyor belt and whether the conveyor line can run smoothly.

1

Method of joint

Conveyor belt joint methods include: mechanical joints, cold bonded joints, hot vulcanized joints and other common methods.

Mechanical joint: generally refers to the use of belt buckle joints. This joint method is convenient, quick and economical, but the joints are low in efficiency and easy to damage, which has a certain impact on the service life of conveyor belt products. In PVC and PVG whole-core flame-retardant and antistatic conveyor belt joints, generally products below grade 8 belts use this joint method.

Cold bonding joints: that is, cold bonding adhesives are used for joints. This joint method is more efficient and economical than mechanical joints. It should have a better joint effect. However, from a practical point of view, because the process conditions are relatively difficult to grasp, and the quality of the adhesive has a great influence on the joint. So it is not very stable.

Thermal vulcanization joints: Practice has proved to be the most ideal joint method, which can ensure high joint efficiency, but also very stable, and the joint life is also very long, which is easy to master. However, there are disadvantages such as troublesome process, high cost, and long joint operation time.

2

Joints for layered conveyor belts

Mechanical joints, cold bonded joints, hot vulcanized joints and other joint methods can be used as required. Generally, cold bonded joints and hot vulcanized joints adopt stepped structure joints.

3

Joint of PVC and PVG whole core flame retardant conveyor belt

Due to the special structure of the whole core belt, the joint is not easy, so most of them adopt mechanical joint method, that is, belt buckle joint. However, in order to ensure the joint effect of belts above grade 8, thermal vulcanization joints are generally used. The structure of the joints are all finger joints. The thermal vulcanization joint process of PVC and PVG whole-core flame-retardant conveyor belts is relatively complicated, and the requirements for equipment are relatively high.

4

Joint of steel cord conveyor belt

The joint of the steel cord conveyor belt is the most complicated of all conveyor belt joint technologies. Not only is the process more complicated, but the joint size parameters are also the most designed. Different types of products have different joint structures. For specific structures, please refer to the GB9770 standard.

In view of the shortcomings of the traditional joint methods mentioned above in the market,At present, a new type of rubber conveyor belt joint method has appeared on the market——Fast seamless conveyor belt joint cover. Fast seamless conveyor belt joint set It is a major reform of the tape joint. Compared with the traditional joint method, it has four significant advantages:Notable advantages such as quick installation, high strength, low consumption and long life.

Four advantages

"fast" That is to say, the connection speed is fast, the connection is completed in about two hours, and the normal production can be put into operation immediately after completion.

"Strong" That is, the connection port has strong tensile force and long service life, which solves the phenomenon of powder leakage of traditional belt buckle joints.

"stable" That is, the operation technology is stable, the process is simple, no professional technicians are required to operate, and ordinary mechanics can fully grasp it, and the joint quality is more stable and reliable than hot glue and cold glue.

"province" That is, the maintenance is simple, the cost is low, and the joint length is saved compared with the traditional joint method.

▷This product has obvious advantages for the joints of high temperature conveyor belts above 200 degrees:

High-temperature adhesive tapes are usually made of EPDM rubber. Because EPDM rubber has poor adhesion and is not easy to secondary vulcanize, high-temperature tape joints are more prone to problems. This joint sleeve breaks the traditional cold and hot glue joints, makes the joints more stable and has a longer service life!

▷Fast seamless conveyor belt joint cover is especially suitable for the joint of whole core flame retardant conveyor belt.

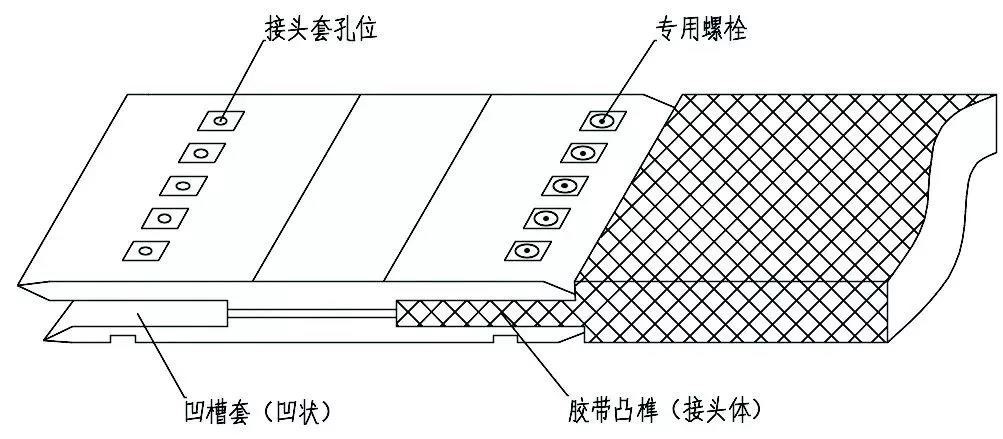

Schematic diagram of the overall structure of the joint sleeve:

The joint sleeve is an open left and right groove sleeve. The groove sleeve is divided into an upper piece and a lower piece. The upper piece has a thick rubber layer and the lower piece has a thin rubber layer. The ends of the upper and lower two pieces have a 20mm slope surface. The open-type left and right groove sleeves match the tenon joint body of the conveying tape joint and form an integral connection structure.

So how to use this set to complete the joint quickly and effectively? Let’s take a look at the method and steps of using this product with Xiaobei:

How to use connector sleeves and steps

1. Make tenons.According to the length of the upper and lower pieces of the joint sleeve, peel off the rubber at both ends of the tape to be jointed to form a tenon; be careful not to damage the fabric (canvas layer) during the peeling and cutting operation. For novices who have no experience in peeling, they can use a roughening machine or a polishing machine (Figure 1).

△Figure 1

2. Apply adhesive.

(1) Clip. First, clamp the two ends of the upper piece of the connector cover (you can use a wire or rope to pass through the screw hole of the connector cover and tie it up) as shown in Figure 2.

△Figure 2

3. Assembly and bonding.

△Figure 3

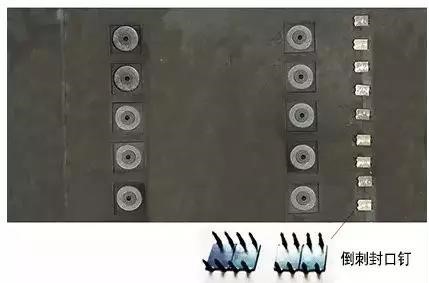

4. Bolt reinforcement

(1) Punch holes. Drill holes of the same size vertically on the tape with a hand electric drill according to the predetermined hole positions on the joint sleeve. (Figure 4)

△Figure 4

(2) Tighten the bolts. Insert the special "special internal thread adhesive tape fixing screw" into the hole on the connector sleeve, and fix it with an Allen screw wrench. (See Figure 5)

△Figure 5

5. Sealing

In order to prevent the edge warping of the joint sleeve during operation, a layer of adhesive can be brushed on the edge of the joint and a row of "barbed sealing nails" can be knocked on (Figure 6).

△Figure 6

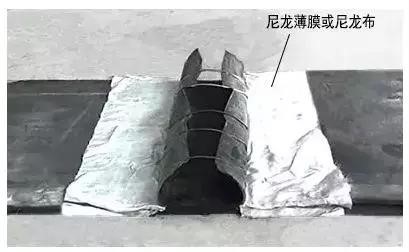

Conveyor belt quick seamless joint sleeve site:

Site map①

Site map②

When the joint sleeve is a tape joint, it not only does not need to lose the length of the joint but also can be extended by about 150mm, so the sleeve can also greatly increase the utilization rate of the waste tape. For example, the waste tape after repair is selected and cut with useful short heads, and the tape can be used again after the joint sleeve is used for quick connection, which greatly saves the cost of the enterprise.

Fast seamless conveyor belt joint sleeve is a new type of rubber conveyor belt joint product developed by Hangzhou Heli Rubber Products Co., Ltd., which won a national invention patent. It was formally approved in July 2012 and became a national innovation fund support project!

The invention of the conveyor belt joint sleeve not only brought major reforms to the belt joint, but also contributed to the development of the industry. It is a good technology and energy-saving product that can help enterprises save labor and costs!

Original author: Hangzhou efforts Rubber Products Co., Ltd.