Technical Services

Hezi technology focuses on the research and development of "rapid seamless conveyor belt joint sleeve" innovative technology project

TECHNICAL SERVICE

Technical Services

Detailed introduction

Technological innovation: fast seamless conveyor belt joint cover version 4.0

Release time:

2019-08-20

The strength at the joints of the conveyor belt is lower than that of the normal belt. Generally, when mechanically connected, the joint strength can only reach 40-50% of the belt strength. When the quality of cold glue is better, the joint strength can reach 60-70%, and the hot glue joint strength can reach 80-90% ( The joint method is correct and there is no quality defect).

The strength at the joints of the conveyor belt is lower than that of the normal belt. Generally, when mechanically connected, the joint strength can only reach 40-50% of the belt strength. When the quality of cold glue is better, the joint strength can reach 60-70%, and the hot glue joint strength can reach 80-90% ( The joint method is correct and there is no quality defect).

Since the strength of the joint is relatively low, if the bonding method is not correct, the strength of the joint will be lower, such as cutting, hurting the next layer of cloth during grinding, excessive grinding, insufficient lap length, insufficient number of steps, and glue joint If the rubber has poor performance or self-vulcanization failure, excessive grinding of the wire rope, rust of the wire rope, etc., the strength of the joint will be greatly reduced, and the joint will be easily disconnected during use. In addition, if the conveyor belt does not use sealing glue, or the direction of the glue joint is wrong, the joint part is prone to cracking (face glue part).

At present, most conveyor belt joints on the market are bonded by adhesives, but such conveyor belt joints are not used for a long time. Once encountered in high temperature, humidity and other environments, the adhesive will fail and become difficult to stick, resulting in It is easy to disconnect and crack, which greatly affects normal production activities.

In view of the limitations of the above-mentioned conveyor belt joints, our company has developed a new conveyor belt joint technology product-"new fast seamless conveyor belt joint sleeve (version 4.0)". Patent number: ZL201721311825.0. This product is based on the invention patent "Quick Seamless Conveyor Belt Joint Cover" (Patent No. ZL200610053597.1) and the latest technology improvement of the assembled tape connection structure (Patent No.: ZL201120111996.5). It solves the problems of difficult bonding, long curing time, and poor bonding effect in special environments such as humidity and high temperature. Make conveyor belt joints more convenient and quicker, more time-saving and labor-saving.

The biggest difference between this joint sleeve and the old product is that adhesives can be omitted. Its advantages are as follows:

1. Installation is faster.No adhesive is used, not only is it easier to operate, but also saves the time of repeated application and curing of the adhesive, making the installation faster.

2. The pulling force is stronger.The combination of special joint bolts and self-tapping screws is adopted to make the joints stronger.

3. More stable performance.The operation process is simpler, and the conveyor belt joint can be easily completed without the need for professional and technical personnel, and the quality is stable and reliable.

4. Wider application range.It does not require professional machinery and equipment, and it can be operated in areas with small on-site environmental space, slopes and high steps, and is not affected by factors such as high temperature and humidity, and the adhesive is not easy to bond.

The following is the use method and joint steps of the new product.

1. Make tenons.

(1) According to the length of the groove in the joint sleeve, peel off the upper and lower rubbers at both ends of the tape to be jointed to form a tenon (the stripping length is about 11cm, according to the joint sleeve of different specifications, peel off after measurement), if necessary For miter joints, measure the length of the bevel and peel off the rubber.

(2) After peeling, if the thickness of the belt exceeds 5mm, you can use a sander to thin the front 1cm of the belt on both sides for installation.

2. Install one end first, then install the other end

Note: The working surface with one groove in the center of the joint sleeve is the non-working surface with three grooves

(1) Insert one end of the stripped belt into the joint sleeve, and after it is completely sleeved, screw in the outermost row of self-tapping screws, and tighten the positioning from the middle to both sides.

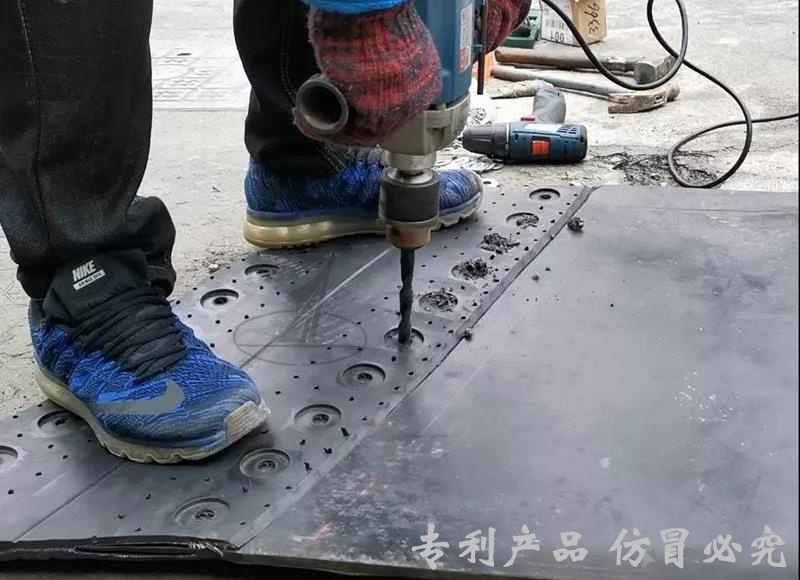

(2) Drill holes of the same size vertically on the tape with a hand electric drill according to the predetermined hole positions on the joint sleeve. Insert the special "special internal thread joint screw" (patent number: ZL201020199652.X) into the hole on the joint sleeve, and tighten it from the middle to both sides with an Allen screw wrench.

(3) Screw in the inner row of self-tapping screws, and tighten them from the middle to both sides.

(4) Repeat the steps (1), (2) and (3) above to install the other end. When installing, make sure that the belts at both ends are in a straight line with the joint.

3. After installation, check the bottom surface of the belt and grind the threads exposed at the bottom of the screw with a grinding wheel polisher to complete the joint.

Installation Precautions:

(1) The width of the joint sleeve must be slightly smaller than the width of the tape to prevent the tape from damaging the joint and affecting its service life.If the width of the joint is larger than that of the tape, the joint will be easily damaged once the tape is off-track. Therefore, the width of the joint must be narrower than the width of the tape. Generally, the width of the joint sleeve is about 10mm narrower than the tape width on each side.

(2) Pay attention to the installation of self-tapping screws. Pay attention to the verticality of the screws when driving self-tapping screws.Special attention: the outermost row of self-tapping screws must not be skewed outwards. The outward skewing will cause the bottom strength layer to be unable to tighten and affect the strength. The length of the screw can be changed; generally, it is advisable to expose the 1-2mm thread at the tip of the self-tapping screw. After tightening all the screws, use a grinding wheel grinder to smooth the exposed screw part on the bottom surface. If the end of the screw is not exposed, you need to replace the long screw of the same model. If you find that the film is not tightened and warped, you can screw up the self-tapping screws from the small holes designed on the bottom to reinforce it.

(3) How to tighten the "special internal thread fixing screw".The internal thread screw should be tightened three times repeatedly. Since rubber is an elastic body, it needs to be tightened gradually, and the general torsion force is 150N-200N. Need to master the principle of "tighten from the middle to both sides". Special attention: After running for a period of time, check whether the screws are loose, and if they are loose, they should be tightened in time.

(4) Stripping method of non-working surface rubber when making tenon.If the conveyor belt is thin, it is difficult to peel off the non-working surface rubber when making the tenon. For those who have no experience in peeling, you can use a sanding machine to remove the rubber; you can also peel off the non-working surface rubber with a layer of cloth. .

Previous Page

Previous Page