Patent name: Guided endless rubber conveyor belt

Patent number: ZL200720003296.8

Summary

The utility model relates to a guided ring-shaped rubber conveyor belt which can prevent the rubber conveyor belt from deviating and shaking from side to side. The rubber conveyor belt comprises a cover rubber and a bottom rubber. The rubber conveyor belt skeleton core is fabric multi-layer or whole fabric core or is composed of thread ropes The wide belt core or the wide belt core composed of steel wire rope, the bottom rubber of the endless rubber conveyor belt is provided with an annular boss or the belt surface of the conveyor belt is concave in cross section, and the two sides of the concave belt surface are L -Shaped limit table. Advantages: First, it not only realizes the production of wide endless conveyor belts, but also has high strength and impact resistance; second, it not only ensures the smooth and stable operation of the endless conveyor belt in the conveying mechanism, but also does not deviate or produce Shake from side to side; the third is to ensure that the conveyed goods will not be scattered outside.

Claims

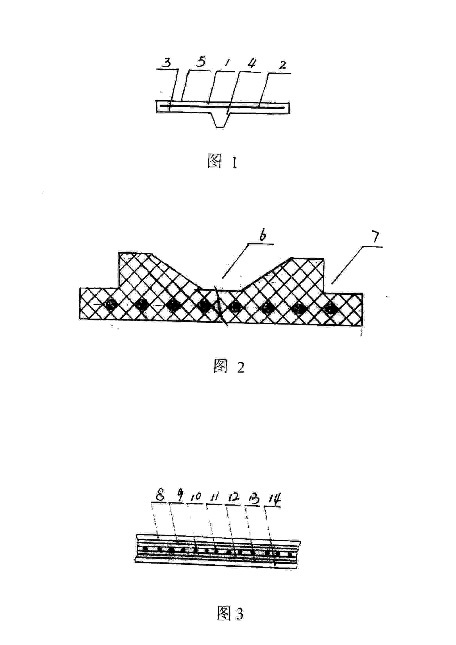

1. A guided endless rubber conveyor belt, which includes a cover rubber (1) and a bottom rubber (3), characterized in that the rubber conveyor belt skeleton core (2) is a multi-layer fabric or a whole fabric core or is composed of a cord The wide belt core or the wide belt core composed of steel wire rope.

2. The guided endless rubber conveyor belt according to claim 1, characterized in that: the bottom rubber part of the endless rubber conveyor belt is provided with one or two or more annular bosses (4).

3. The guided annular rubber conveyor belt according to claim 2, characterized in that the bottom of the annular boss (4) and the annular rubber conveyor belt form an integral structure, and the end width is smaller than the bottom.

4. The guided endless rubber conveyor belt according to claim 1, characterized in that: the belt surface (5) of the conveyor belt is flat or herringbone or T-shaped surface or surface with ribs.

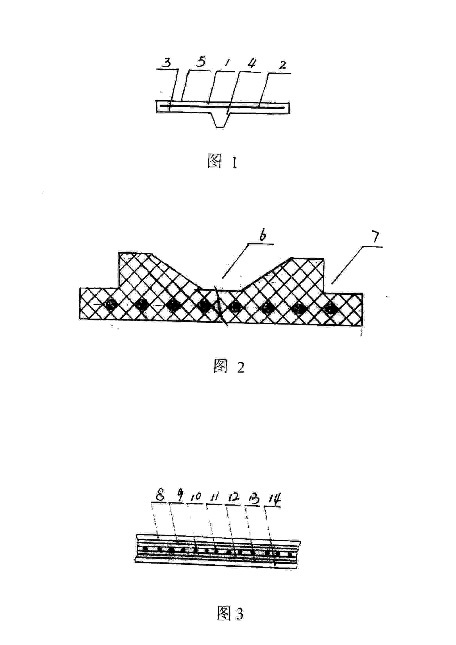

5. The guided endless rubber conveyor belt according to claim 1, characterized in that the belt surface of the conveyor belt is a concave surface (6) in transverse cross-section, and the two sides of the concave belt surface are L-shaped limit tables (7). ).

6. The guided endless rubber conveyor belt according to claim 5, characterized in that the concave belt surface (6) is trumpet-shaped in section.

Technical field

The utility model relates to a guided ring-shaped rubber conveyor belt which can prevent the rubber conveyor belt from deviating and shaking from side to side, and belongs to the field of manufacturing of ring rubber conveyor belts.

Background technique

In the structure design of the existing endless rubber conveyor belt, the rubber conveyor belt itself does not have a structure to prevent it from shaking and deviation. Therefore, when the rubber conveyor belt runs on the conveyor roller, it is easy to run off and has a short service life. , The second is shaking left and right, which affects the conveying effect and is unsafe.

Summary of the invention

Design purpose: to avoid the shortcomings in the background technology, to design a guided endless rubber conveyor belt that can be equipped with a structure that can prevent its deviation and shaking in the rubber conveyor belt.

Design:

1. On the basis of the existing endless conveyor belt, the rubber conveyor belt skeleton core adopts a high-strength fabric multilayer or a whole fabric core or a wide belt core composed of wire rope or a wide belt core composed of steel wire rope. One of the features of this utility model. The purpose of adopting the above-mentioned belt core is: because of the high-strength multi-layer fabric or the whole fabric core or the wide belt core composed of wire ropes or the wide belt core composed of steel wire ropes, not only the width is wide, but also the strength is high, which can meet the high strength And the wide endless conveyor belt is made to meet the transportation requirements of bulk cargo such as coal.

2. The design of the annular boss of the bottom rubber part of the endless rubber conveyor belt is the second feature of this utility model. The ring-shaped boss matches the ring-shaped concave shape in the conveying mechanism, which can ensure the smooth and stable operation of the rubber conveyor belt in the conveying mechanism without deviation or shaking from left to right, ensuring the safe transportation of goods.

3. The design that the belt surface of the conveyor belt has a concave surface in transverse cross-section and the two sides of the concave surface have L-shaped limit tables is the third feature of the present invention. Due to the concave surface of the conveyor belt surface, it can ensure that the center of gravity of the bulk cargo on the conveyor belt falls into the concave surface of the conveyor belt during the conveying process, so the goods will not be scattered outside the conveyor belt; and the concave shape The matching of the L-shaped limit table on both sides of the belt surface with the limit roller on its side can ensure the smooth and stable operation of the endless conveyor belt in the conveying mechanism, and will neither run off nor produce side-to-side shaking, ensuring that Safe transportation of goods.

Technical Solution 1: Guided endless rubber conveyor belt, which includes cover rubber (1) and bottom rubber (3). The rubber conveyor belt skeleton core (2) is a multi-layer fabric or a whole fabric core or a wide belt composed of threads A core or a wide belt core composed of steel cords, and one or two or more annular bosses (4) are arranged in the middle of the bottom rubber of the annular rubber conveyor belt.

Technical Solution 2: Guided endless rubber conveyor belt, which includes cover rubber (1) and bottom rubber (3). The rubber conveyor belt skeleton core (2) is a multi-layer fabric or a whole fabric core or a wide belt composed of threads The core or the wide belt core composed of steel ropes, the belt surface of the conveyor belt transversely cuts into a concave belt surface (6), and the two sides of the concave belt surface are L-shaped limit tables (7).

Compared with the background technology, the utility model is compared with the background technology. First, the rubber conveyor belt skeleton core adopts high-strength fabric multi-layer or whole fabric core or wide belt core composed of wire rope or wide belt core composed of steel wire rope, which not only realizes the wide The production of endless conveyor belts has high strength and impact resistance; the second is the design of the annular boss of the bottom rubber part of the endless rubber conveyor belt or the design of the L-shaped limit table on both sides of the concave belt of the endless rubber conveyor belt, which not only ensures The endless conveyor belt runs smoothly and steadily in the conveying mechanism, and it will neither deviate nor produce side-to-side shaking; third, the design of the concave conveyor belt surface ensures that the conveyed goods will not be scattered outside.

Description of the drawings

Figure 1 is a schematic structural view of a first embodiment of a guided endless rubber conveyor belt.

Figure 2 is a schematic structural view of a second embodiment of a guided endless rubber conveyor belt.

Fig. 3 is a schematic diagram of the structure of a guided endless rubber conveyor belt composed of a steel cord core.