Technical Services

Hezi technology focuses on the research and development of "rapid seamless conveyor belt joint sleeve" innovative technology project

TECHNICAL SERVICE

Technical Services

Detailed introduction

About the purpose of installing horizontal thin wire ropes on wire rope conveyor belts

Release time:

2012-12-28

In the transportation industry, steel wire rope conveyor belts are divided into hoisting steel wire belts and horizontal conveying steel wire belts. According to the direction of operation, they are divided into two types: parallel or vertical operation. The lifting tape is a vertical movement. In order to improve the service life of the wire rope hoisting tape, the key is to prevent tearing and cracking.

In the transportation industry, steel wire rope conveyor belts are divided into hoisting steel wire belts and horizontal conveying steel wire belts. According to the direction of operation, they are divided into two types: parallel or vertical operation. The lifting tape is a vertical movement. In order to improve the service life of the wire rope hoisting tape, the key is to prevent tearing and cracking.

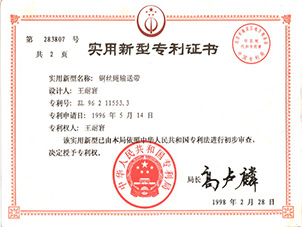

As early as 1996, our company has successfully applied for a patent for laying horizontal thin steel wire with steel wire belt, national patent number: ZL96211553.3.

This patent uses a unique design to solve the problem of anti-tearing and anti-cutting on each unit area of the steel wire lifting tape. Using the method of crisscrossing, horizontal thin wire ropes are arranged on both sides of the longitudinal wire ropes, under the action of the transverse wire ropes, the forces on the longitudinal wire ropes are more consistent during operation, thereby further preventing the longitudinal wire ropes from being torn and split.

1. The principle of the longitudinal steel wire rope being torn and split: the steel wire rope lifting tape head wheel hangs in the air. When the tape passes the head wheel, the longitudinal steel wire rope receives gravity and tension and transmits the force to the rubber. At this time, the rubber is repeatedly fatigued and is in a position where the force is large. The wire rope is cut out first after the rubber is aged in advance.

2. This patent is provided with a rubber barrier on both sides of the longitudinal steel wire rope and the horizontal steel wire rope. The purpose is to use the rubber barrier as a buffer layer after the longitudinal steel wire rope is stressed to prevent the longitudinal steel wire rope from cutting the rubber layer in turn. After the horizontal steel wire rope is installed, the overall force is crisscrossed.

3. The transverse steel wire designed by this patent has a diameter of 1 mm, is buried on both sides, one with a density spacing of 10 mm, one on top and one on the top, each with a tensile force of 1100N*2=2200N. It is more than twice as strong as ordinary canvas tape with 4 layers of canvas core. Generally, the strength of the steel wire rope lifting tape refers to the diameter and number of the longitudinal steel wire ropes. Larger diameters of the same specification can reduce the number, and vice versa. The horizontal steel wire rope should not be thick, because the horizontal steel wire will occupy a lot of space, and the thickness of the whole tape is often increased, otherwise the rubber layer is thin and the tape service life will be affected.

Patent inventor: Wang Naiqian