PRODUCTS CENTER

Rubber filter belt, filter machine belt (vacuum belt)

Product Classification:

Key words:

Rubber filter belt, filter machine belt (vacuum belt)

For more information, please contact us directly by phone or email

Number of views:

1000

Product Description

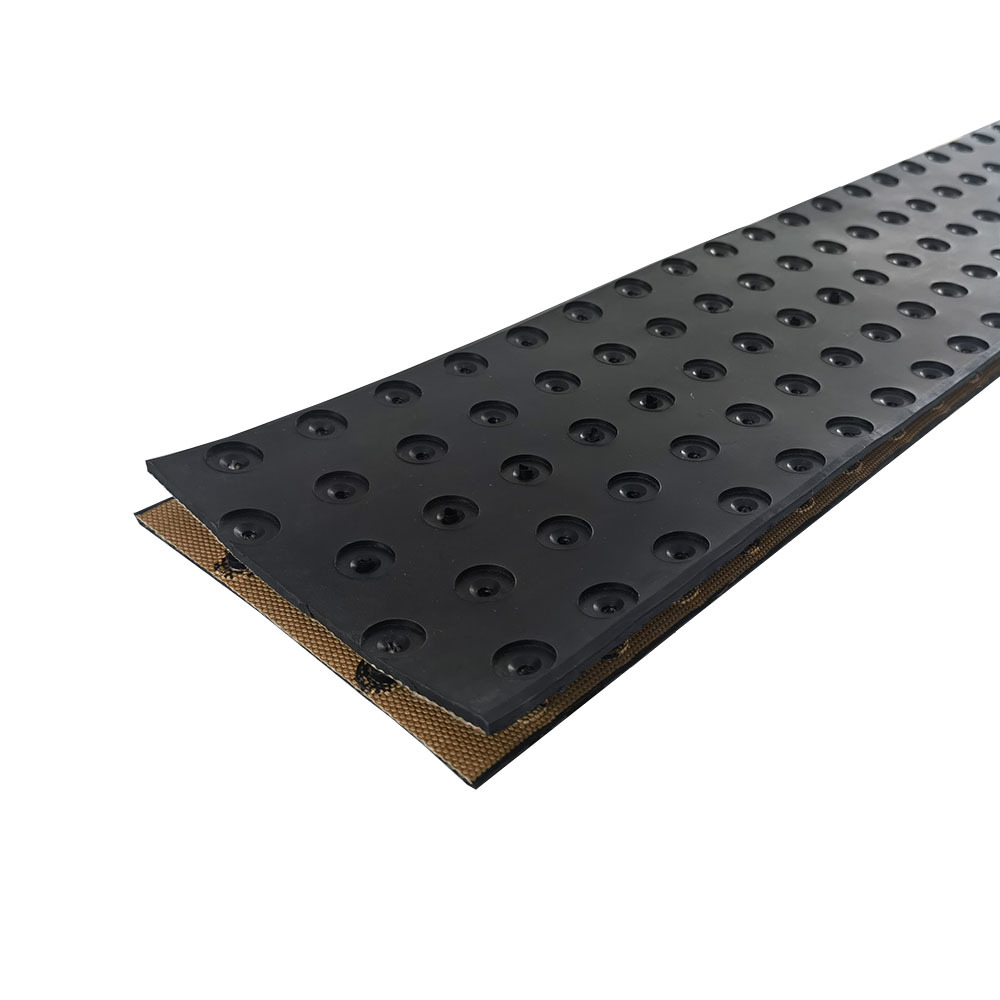

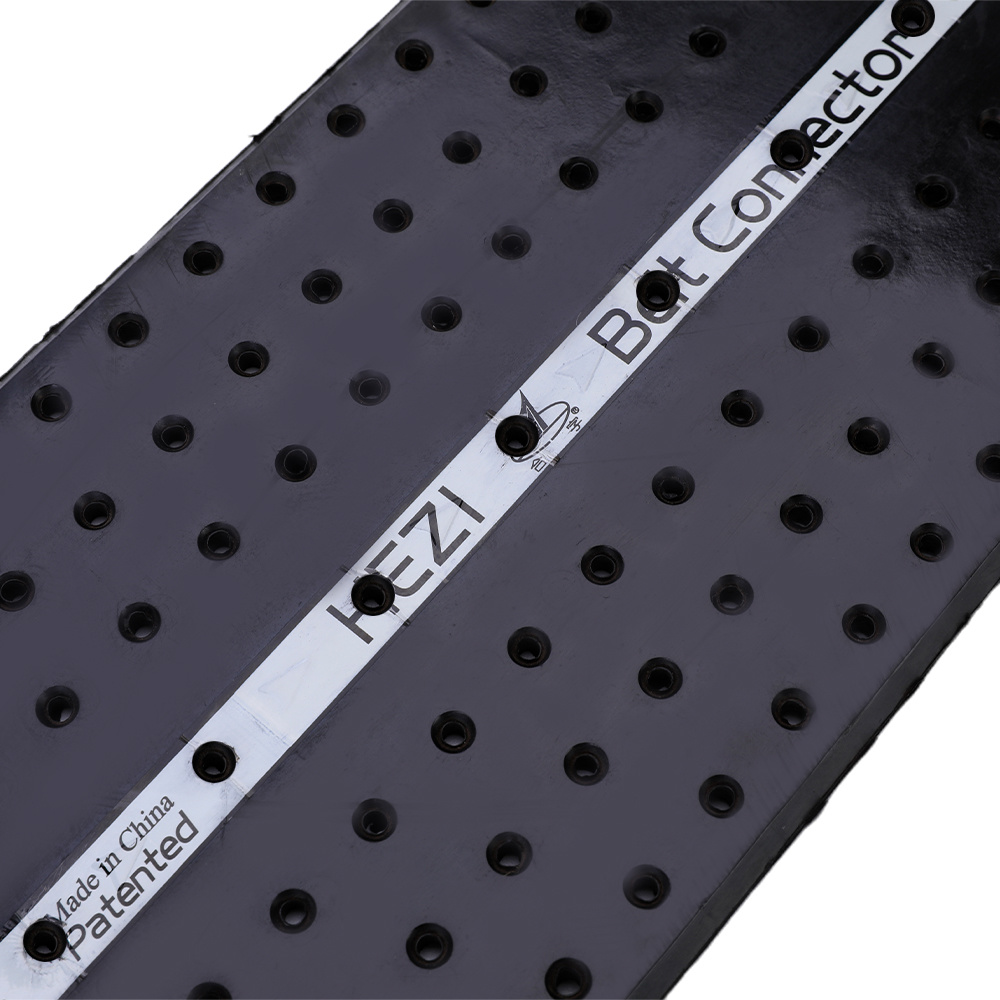

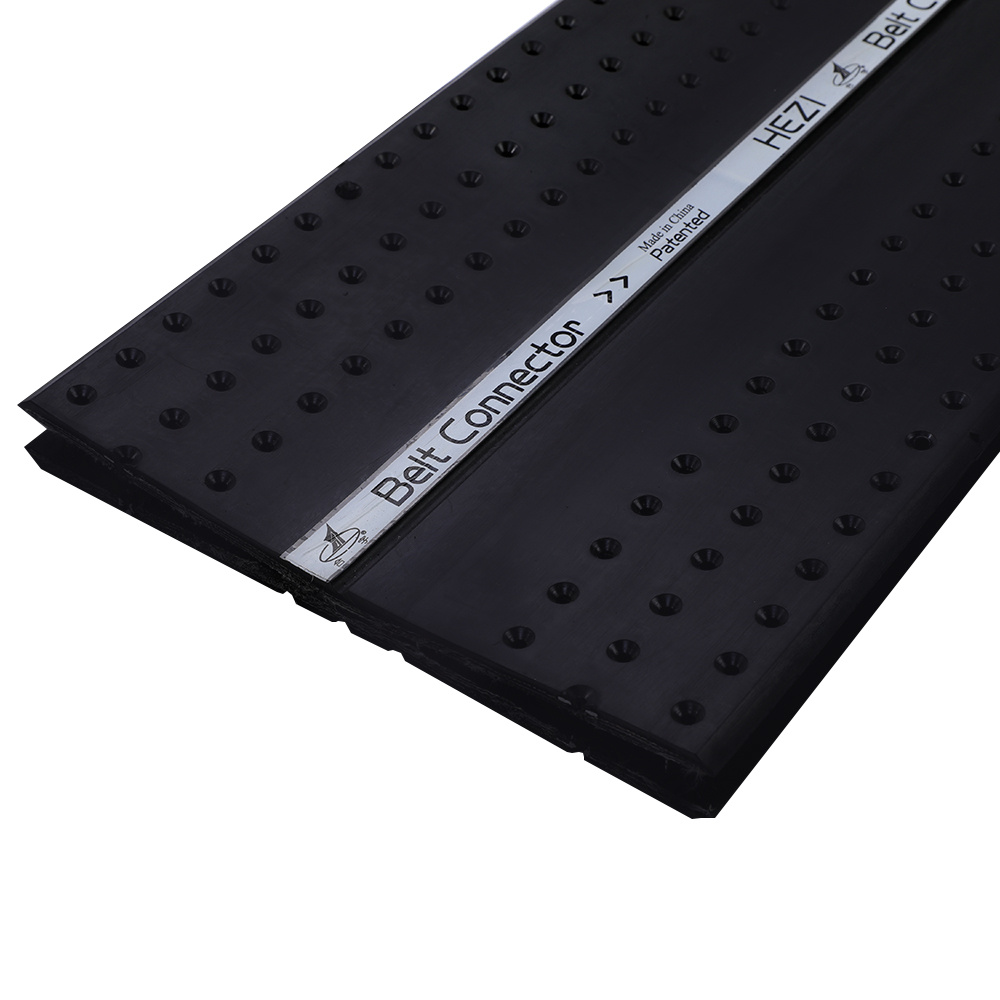

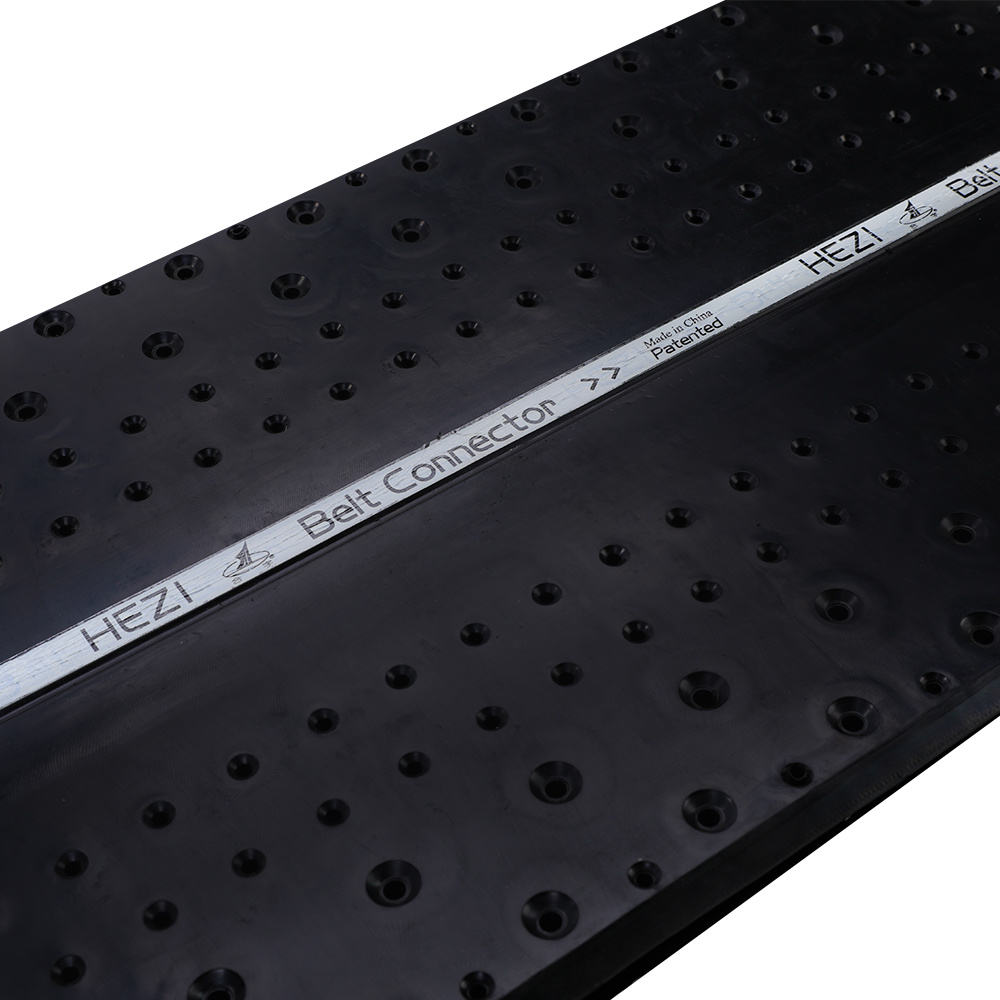

The rubber belt fastener is a reliable and efficient solution for connecting and repairing conveyor belts in various industries, including mining, construction, and manufacturing. Designed for quick installation and long-lasting performance, this rubber belt fastener ensures secure belt joints without compromising belt integrity. Made from durable, wear-resistant materials, the rubber belt fastener provides strong holding power and resists vibration, tension, and heavy loads. It is ideal for both temporary fixes and permanent belt splicing, allowing for reduced downtime and increased productivity. Compatible with a wide range of rubber belt types, the rubber belt fastener offers flexibility and ease of use, making it a preferred choice for field maintenance and on-site repairs. Whether used in harsh or high-impact environments, this rubber belt fastener delivers consistent, dependable performance, ensuring your conveyor system runs smoothly and efficiently.

Rubber filter belts, also known as vacuum belts, are key components of vacuum belt-type washing machines and DU horizontal belt vacuum filters.

Features:

The surface of the belt body has a row of transverse grooves, with one or more rows of drainage holes in the grooves. The drainage hole section can use a pure rubber structure; the skeleton layer of the belt body is made of high-strength polyester canvas or nylon canvas; the upper and lower covering rubber of the filter belt can use different formulas according to working conditions to meet various needs such as acid and alkali resistance, heat resistance, oil resistance, and cold resistance; the molding and vulcanization of the rubber belt adopt a one-time overall composite process, ensuring the flatness of the belt body and the stability of its performance.

Acid and alkali resistant filter belt

Suitable for working environments that come into contact with acids and alkalis, such as: phosphate fertilizer, alumina, catalysts (4A zeolite), and other industries. The covering rubber uses a rubber-plastic blend material filled with acid and alkali resistant inert media, which has superior acid and alkali resistance compared to chloroprene rubber; the skeleton material uses high-strength polyester canvas, which has stronger acid and alkali resistance than cotton canvas; the drainage hole section uses pure rubber, effectively blocking the corrosion of acid and alkali liquids on the skeleton layer, significantly extending the service life of the filter belt.

Heat resistant filter belt

Mainly used for filtering high-temperature materials, with a heat resistance temperature of 800C < heat resistance temperature < 1050C. The covering rubber uses a thermoplastic elastomer with excellent heat resistance and aging resistance; the skeleton layer uses high-strength polyester canvas, and heat-resistant glass cloth can be laid between the covering rubber and the skeleton layer; the drainage hole section uses a pure rubber structure, effectively blocking the impact of high temperature and filtrate on the skeleton material; the service life of the filter belt is significantly improved.

Oil resistant filter belt

Suitable for filtering environments containing various oily materials. The covering rubber uses nitrile rubber with a high acrylonitrile content, and the skeleton layer uses high-strength polyester canvas. It has advantages such as low deformation and change rate of the belt body, high strength, and wide range of use.

Cold resistant filter belt

Suitable for working environments with temperatures ranging from -40C to +70C. The skeleton layer uses polyester canvas, and the covering rubber uses a combination of natural rubber and polybutadiene rubber, featuring high elasticity, impact resistance, and cold resistance.

Customer Message

Dear customer, if you have any comments or suggestions about our products or services, please let us know in a timely manner and we will reply to you as soon as possible.

Related Products