PRODUCTS CENTER

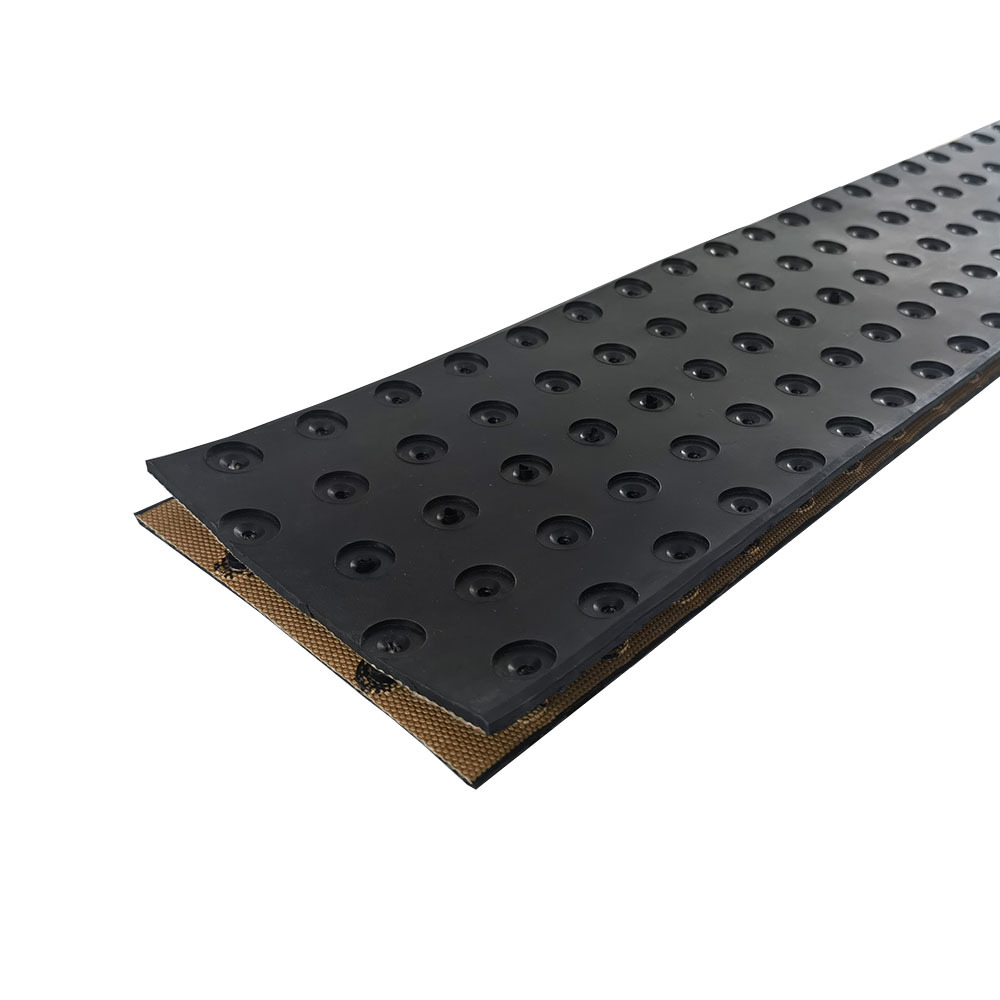

Double-sided tear resistant Steel core elevator belt

Product Classification:

Key words:

Double-sided tear resistant Steel core elevator belt

For more information, please contact us directly by phone or email

Number of views:

1000

Product Description

Performance description: Anti-tear type steel core elevator belt adopts high strength wire rope. The structure is divided into two types: adding buffer layer as transverse reinforcement and adding transverse parts as transverse reinforcement. After the cold pressing molding core glue and cover glue, after the vulcanization process.

The tensile strength, good impact resistance, long life, use of small elongation, good groove, good flexural flexibility suitable for long distance, large transportation, high speed conveying materials.

Application:

Widely used in coal, mining, building materials cement, port, metallurgy, electricity, chemical and other fields of transport materials.

Tensile strength:

630~7500N/mm Width: 250~1300mm.

Characteristics and advantages:

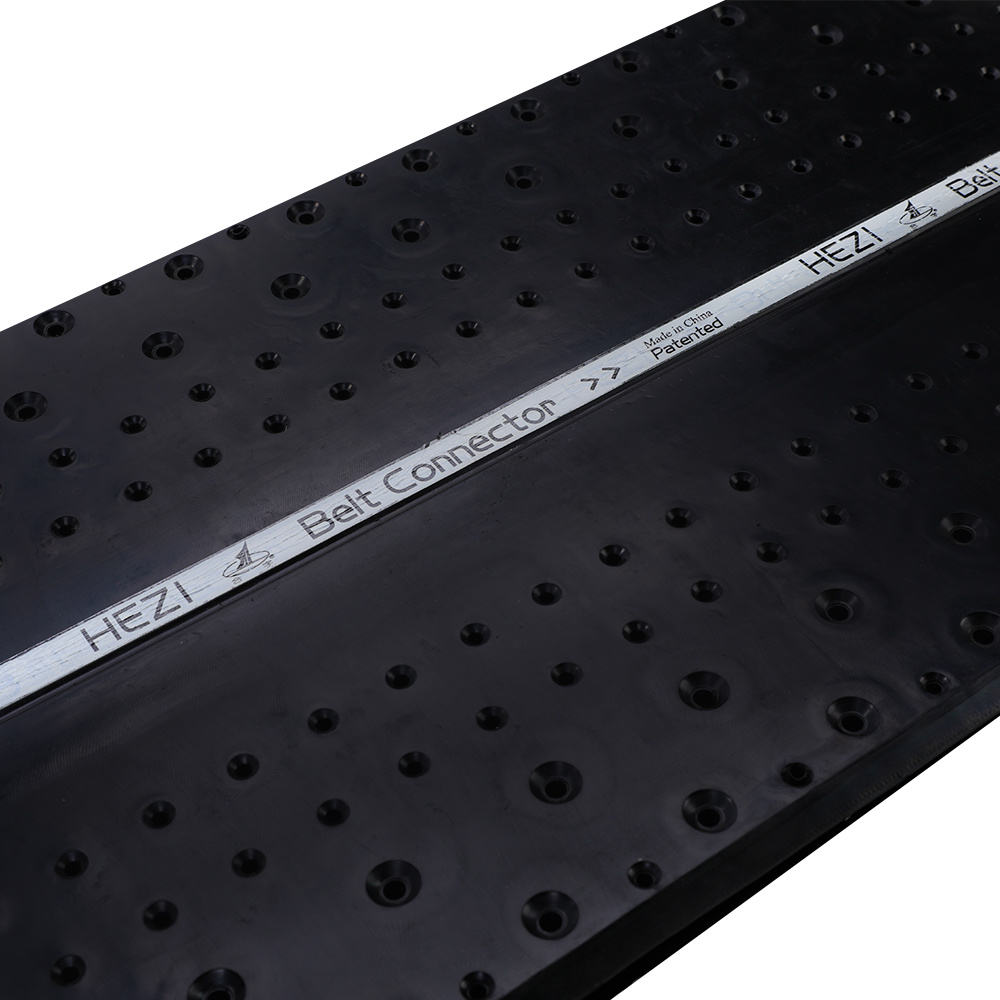

1. The use of galvanized open wire rope

Select galvanized open wire rope to meet all kinds of special needs. The wire rope has high elasticity and low elongation, and high joint efficiency can also be obtained. galvanized wire rope can be tightly bonded with core glue to form a protective layer against corrosion.

2. High power

Wire rope core lift belt can meet the most customer application requirements, continuous research and development of higher strength conveyor belt to fill the higher lifting system.

3.High impact resistance.

Our cover glue and core glue tighter bonding, can provide good impact and tear resistance.

4, lower unit transport cost.

Fewer conveyors and joints, shorter tensioning trips and reduced conveyor belt inventory all save investment costs. longer conveyor belt and joint working life, reduce downtime, reduce unit delivery cost.

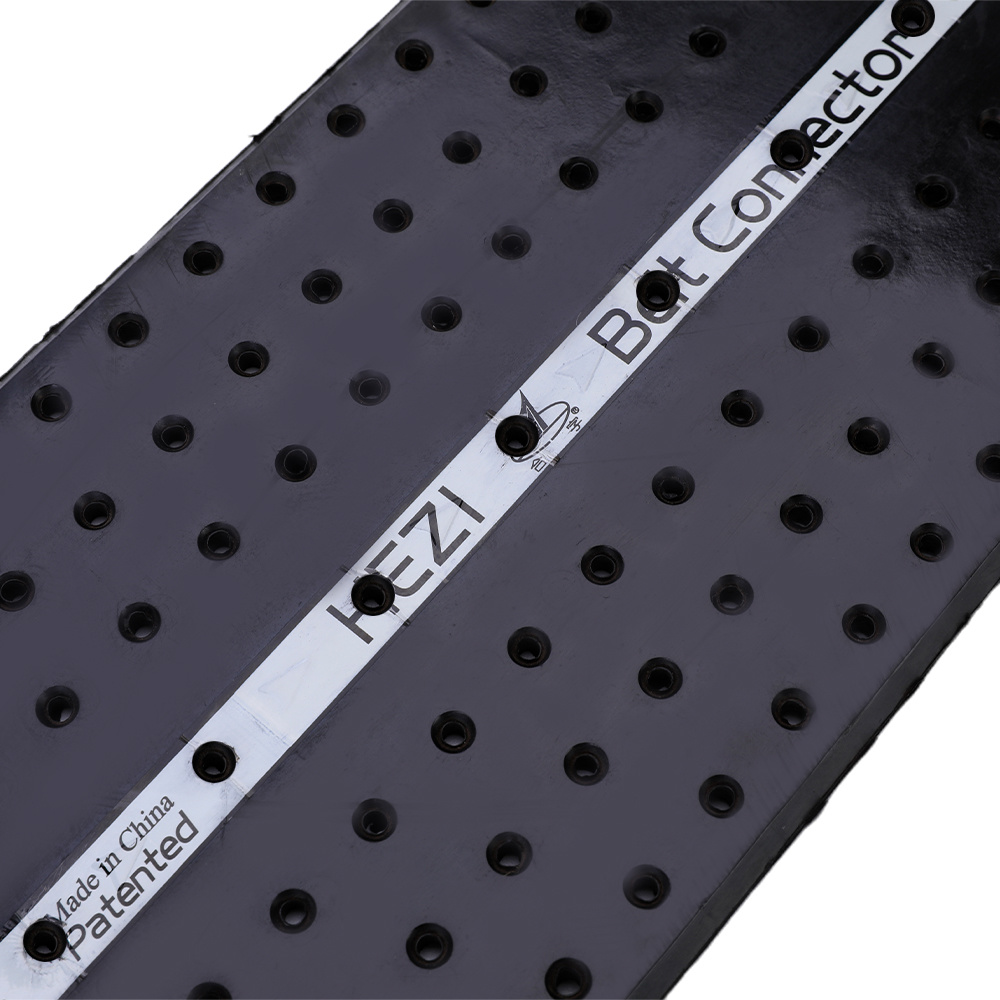

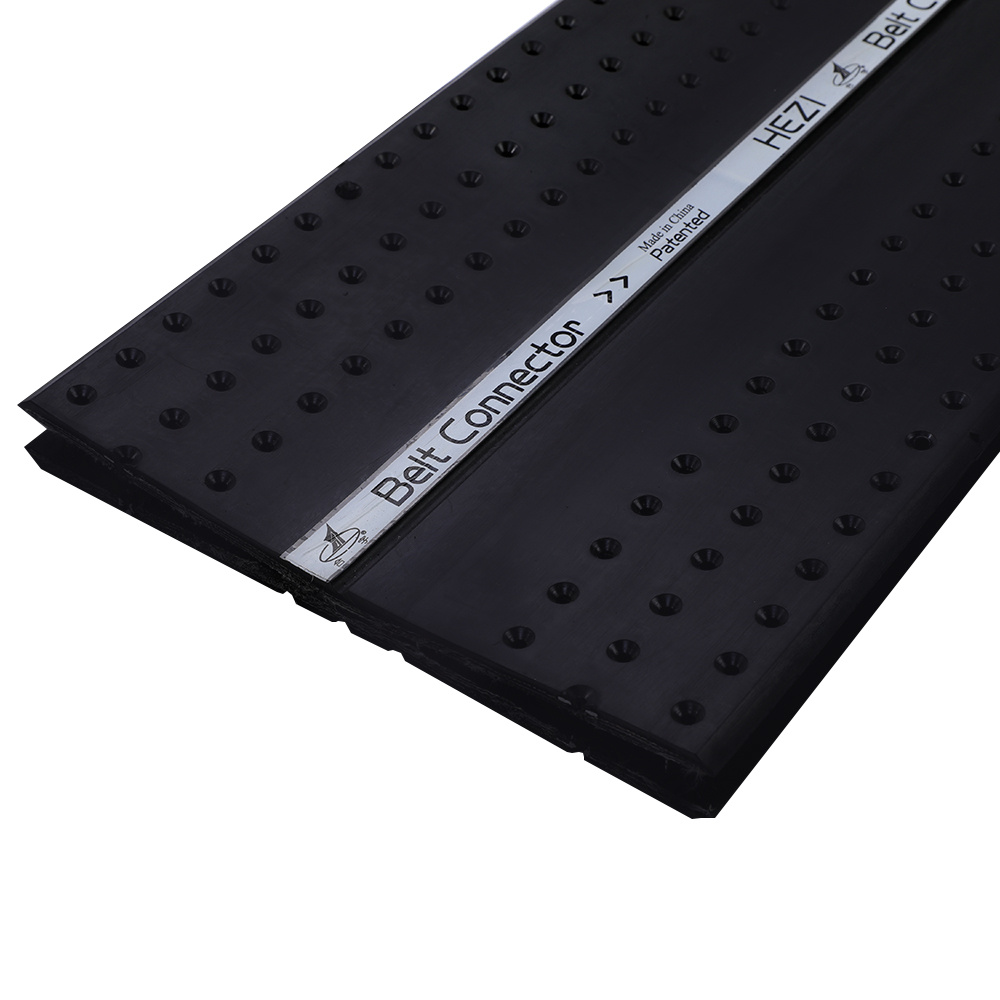

Our company produces steel core elevator belt using two patented technology:

1. Patented technology to solve the easy to break at the joint site - the cord-coated canvas structure at the wire rope lifting tape joint (patent number ZL200920119059.7).

Core technology: the joint position double-sided with high-strength fabric cord canvas or short-fiber rubber, so as to enhance the overall hardness of the joint, eliminate rubber fatigue aging. extended the service life of the wire rope elevator belt.

2. Patented technology for solving elevator belt hopper easy to fall off (patent number ZL200920119058.2).

Core technology: vertical steel wire ropes are arranged in combination, and the steel wire rope shall be avoided during drilling(without breaking the wire rope);At the same time, the longitudinal steel wire rope is stuck with the hopper bolt inverted, so as to enhance the overall strength of the wire rope lifting belt, prevent the hopper from falling and extend the service life.

See the technical article section for how to extend the service life of steel core evaluator belt http://www.hl-xj.com/Article/D2.html

See technical article area http: //www.hl-xj.com/Article/D2.html.

Previous article

Next article

Customer Message

Dear customer, if you have any comments or suggestions about our products or services, please let us know in a timely manner and we will reply to you as soon as possible.

Related Products